Sheet metal forming processes this is a commonly used manufacturing process that helps in manufacturing the parts for tons of known and unknown purposes.

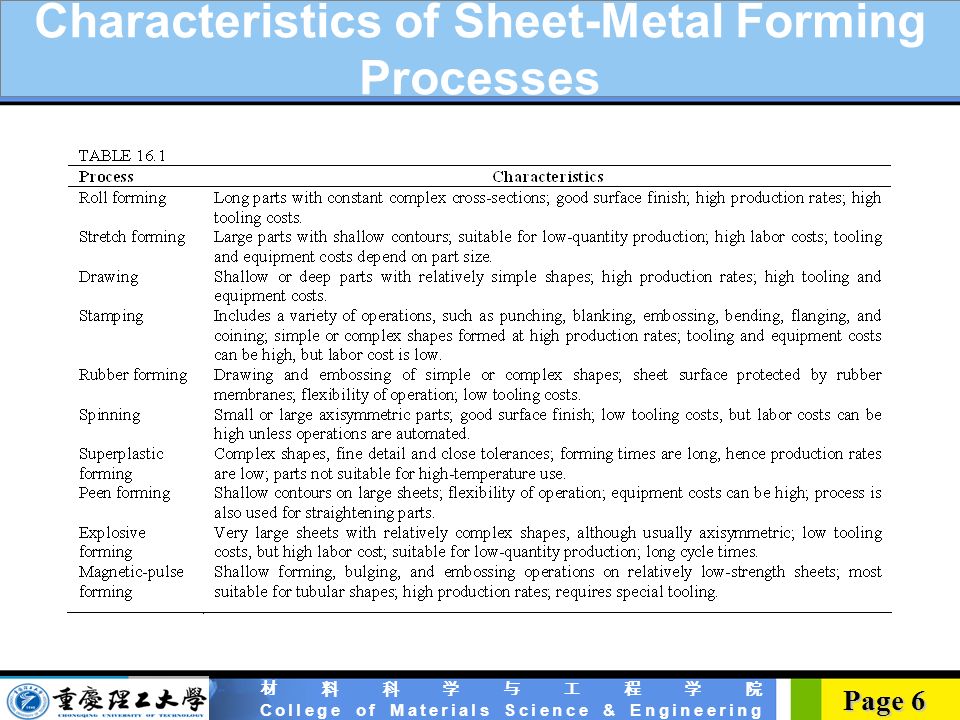

Characteristics of sheet metal forming.

The press is usually not yet known so that its characteristics are rather a factor of noise than a useful information.

All other factors influencing sheet metal forming we should recall that a sheet metal forming operation can always be from the conceptual point of view.

Curling is a sheet metal forming process that s used to smooth out the otherwise sharp and rugged edges of sheet metal.

When making sheet metal however companies often use one or more of the following forming processes.

Sheet metal is metal formed by an industrial process into thin flat pieces.

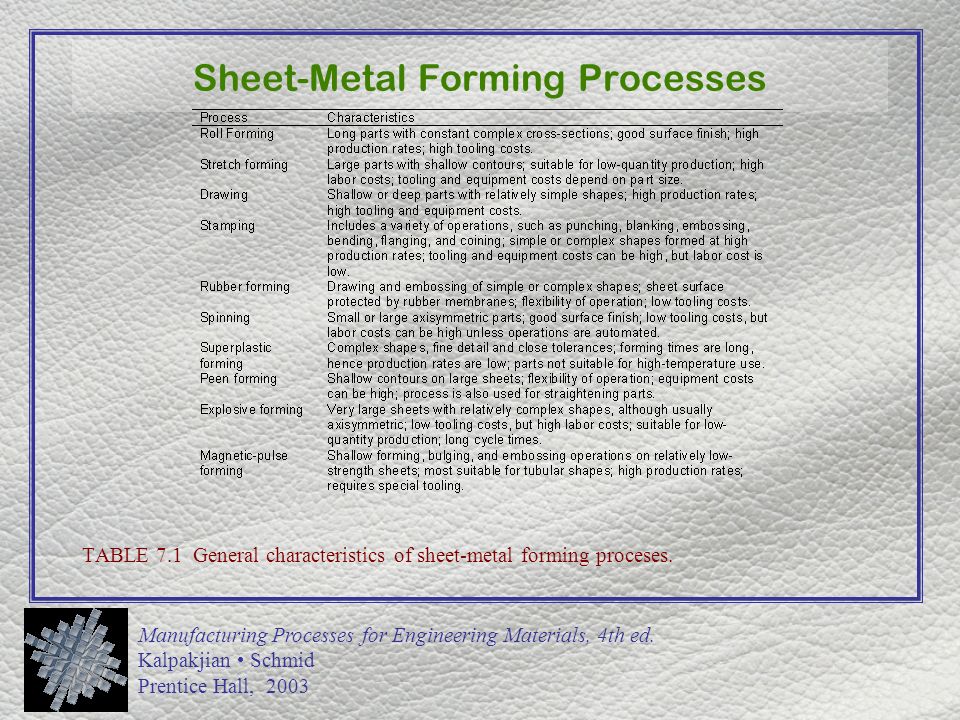

Classification of basic sheet forming processes.

On the industrial scale forming is characterized by.

Therefore it will be important to have a design that.

Good surface þni sh.

It is the maximum stress that the cross section is subjected to when the load is applied between the two points of the specimen.

N mm2 or mpa the symbol is σb.

Sheet metal forming involves forming and cutting operations performed on metal sheets strips and coils.

Sheet metal roll forming roll forming of sheet metal is a continuous manufacturing process that uses rolls to bend a sheet metal cross section of a certain geometry.

It is one of the indexes of metal strength.

Stretch form ing large parts with shallow contours.

Countless everyday objects are fabricated from sheet metal.

Pr ocess characteristics roll forming long parts with constant complex cross sections.

Often several rolls may be employed in series to continuously bend stock.

Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes.

Sheet metal forming process is done on a press and the parts are formed in between two die.

Sheet metal forming processes table 7 1 general characteristics of sheet metal forming processes.

It is the maximum stress that the sheet metal material is subjected to before pulling out.

It is customary to refer to a material below the thickness of 6 35 mm as a sheet and thicker materials as plate.

Because this book is limited to bend forming which is the simplest of sheet metal forming operations the basic discussion is limited to bending.

Similar to shape rolling but.

Very high loads and stresses required between 50 and 2500 n mm2 7 360 ksi.

Tools include punch die that are used to deform the sheets.

Sheet metal often contains sharp edges with burrs after it s initially produced.

The die at the top is called a punch.

Suitabl e for low quan tity production.